Stainless Steel OP431 Powder

Overview of Stainless Steel OP431 Powder OP431 stainless steel belongs to the ferritic grade steels which contain chromium as the principal alloying element. The addition of aluminum enhances oxidation and corrosion resistance at high temperatures. Key characteristics of OP431 powder include: Excellent oxidation and corrosion resistance up to 1150¡«C Good creep resistance and thermal fatigue…

Malé MOQ

Flexibilní zásobování stovkami produktů

Podpora přizpůsobení

Prášek na míru podle odvětví

Rychlé odeslání

DHL Express, bezpečně a rychle přímo do vašich rukou

Overview of Stainless Steel OP431 Powder

OP431 stainless steel belongs to the ferritic grade steels which contain chromium as the principal alloying element. The addition of aluminum enhances oxidation and corrosion resistance at high temperatures.

Key characteristics of OP431 powder include:

- Excellent oxidation and corrosion resistance up to 1150¡«C

- Good creep resistance and thermal fatigue strength

- Excellent thermo-mechanical stability

- High thermal conductivity and low thermal expansion

- Cost-effective compared to austenitic stainless steels

- K dispozici v různých distribucích velikosti částic

OP431 powder is ideal for applications requiring oxidation resistance, thermal stability and moderate strength at elevated temperatures.

Chemical Composition of OP431 Powder

OP431 powder has the following nominal composition:

| Element | Hmotnostní % |

|---|---|

| Železo (Fe) | Balance |

| Chrom (Cr) | 16-18% |

| Hliník (Al) | 3-5% |

| Yttrium (Y) | 0.2-0.5% |

| Uhlík (C) | max. 0,03 % |

| Křemík (Si) | 1 % max. |

| Mangan (Mn) | 1 % max. |

Chromium provides corrosion resistance while aluminum enables excellent oxidation resistance through formation of a protective alumina layer at high temperatures. Yttrium refines the grain size for additional strength.

Properties of OP431 Powder

Key properties of OP431 powder include:

| Nemovitost | Hodnota |

|---|---|

| Hustota | 7,3 g/cm3 |

| Teplota tání | 1400-1450 |

| Tepelná vodivost | 29 W/mK |

| Elektrický odpor | 0.6 Ã×´Î.cm |

| Youngův modul | 200 GPa |

| Poissonův poměr | 0.27-0.30 |

| Pevnost v tahu | 450-650 MPa |

| Mez kluzu | 280-480 MPa |

| Prodloužení | 15-20% |

| Oxidační odolnost | Výborná až do 1150 ¡«C |

The properties like high temperature strength, oxidation resistance, and thermal stability make OP431 suitable for demanding applications.

Production Method for OP431 Powder

OP431 powder can be produced via:

- Plynulá atomizace?- High pressure inert gas used to atomize the molten alloy resulting in fine spherical powder ideal for AM.

- Atomizace vody?- High velocity water jet breaks up the molten stream producing irregular powder particles. Lower cost but higher oxygen pickup.

- Mechanické legování?- Mletí směsi prvků v kulovém mlýnu, následné spékání a sekundární atomizace.

Gas atomization allows excellent control over particle size distribution, morphology, oxygen pickup and microstructure.

Applications of OP431 Powder

Typical applications of OP431 powder include:

- aditivní výroba?- Selective laser melting to produce complex parts needing high temperature oxidation resistance.

- Tepelné povlaky?- Applied via arc spraying to provide protective coatings on components operating at over 1000¡«C.

- Pájecí přísada?- For joining ferritic stainless steel parts in high temperature applications.

- Zapalovače tuhých paliv?- Powder metallurgy igniter plugs used in industrial furnaces and turbines.

- Zpracování roztaveného kovu?- Powder metallurgy conveyor rolls, tundishes and ladles used in molten metal handling.

Specifications of OP431 Powder

OP431 powder is available under various size ranges, shapes and grades:

- Velikost částic:?15 až 45 µm pro AM metody, až 150 µm pro procesy tepelného stříkání.

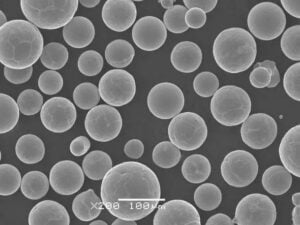

- Morfologie:?Sférické, nepravidelné a smíšené tvary. Sférický prášek má vynikající tekutost.

- Čistota:?From commercial to high purity grades based on application requirements.

- Obsah kyslíku:?Hladiny udržované pod 2000 ppm pro většinu aplikací.

- Průtok:?Powder can be customized for flow rates above 25 s/50 g.

Global Suppliers of OP431 Powder

Some of the major global suppliers of OP431 powder include:

- Sandvik Osprey (UK)

- Hoganas (Švédsko)

- Carpenter Powder Products (USA)

- Praxair Surface Technologies (USA)

- CNPC Powder Group (Čína)

These companies produce various grades of OP431 powder tailored for additive manufacturing, thermal spray, powder metallurgy and other high temperature applications.

Pricing of OP431 Powder

OP431 powder is priced higher than austenitic grades but lower than exotic alloys:

- Množství?- $50-100 per kg for bulk orders above 500 kg. Smaller quantities are priced significantly higher.

- Kvalita?- High purity, spherical powder with controlled characteristics demands premium pricing.

- Dodavatel?- Large global suppliers offer competitive pricing owing to higher volumes.

- Zeměpis?- Prices vary between regions with Europe and North America being higher priced markets.

For critical applications, buyers should focus on quality rather than lowest cost while procuring OP431 powder.

Storage and Handling of OP431 Powder

OP431 powder requires the following storage and handling:

- Aby se předešlo oxidaci, skladuje se v zapečetěných nádobách s inertním plynem

- Avoid accumulation of fine powder to minimize dust explosion risks

- Use proper PPE, ventilation, grounding and safety practices during handling

- Zabraňte styku s prášky a nekompatibilními materiály

- Follow safety guidelines provided by supplier SDS

Proper protective measures must be taken when handling this reactive alloy powder.

Inspection and Testing of OP431 Powder

Key quality control tests performed on OP431 powder include:

- Chemická analýza pomocí OES nebo XRF pro zajištění toho, že složení bude splňovat stanovené limity

- Distribuce velikosti částic dle normy ASTM B822

- Morfologická analýza pomocí SEM

- Průtok prášku měřený podle normy ASTM B213

- Oxygen and nitrogen content testing by inert gas fusion

- Density determined by helium pycnometry

- Microstructure characterization by XRD

Thorough testing ensures the powder meets the required chemical, physical and microstructural characteristics for the intended application.

Comparison Between OP431 and 316L Stainless Steel Powders

OP431 and 316L stainless steel powders are compared:

| Parametr | OP431 | 316L |

|---|---|---|

| Typ | Ferritic | Austenitic |

| Obsah Cr | 16-18% | 16-18% |

| Ni content | – | 10-14% |

| Pevnost za vysokých teplot | Vyšší | Nizší |

| Odolnost proti korozi | Střední | Výborný |

| Cena | Nizší | Vyšší |

| APLIKACE | Thermal spray, igniters | Automotive, construction |

| Schweißbarkeit | Špatné | Výborný |

OP431 offers much better high temperature strength whereas 316L provides excellent fabrication characteristics and corrosion resistance.

OP431 Powder FAQs

Q: How is OP431 powder produced?

A: OP431 powder is commercially produced using gas atomization, water atomization, and mechanical alloying followed by sintering. Gas atomization provides the best control of powder characteristics.

Q: What are the main applications of OP431 powder?

A: Key applications include thermal spray coatings, additive manufacturing, brazing filler, powder metallurgy igniter plugs, and high temperature molten metal handling components where oxidation resistance is needed.

Q: What is the typical OP431 powder size range used in metal AM?

A: For most metal AM processes, the ideal OP431 powder size range is 15-45 microns with spherical morphology and good powder flow characteristics.

Q: Does OP431 powder require any special handling precautions?

A: Yes, it is recommended to handle this reactive powder carefully under inert atmosphere using proper ventilation, grounding, and PPE.

Q: Where can I purchase OP431 powder suitable for thermal spray coatings?

A: For thermal spray applications requiring high temperature oxidation resistance, OP431 powder can be purchased from leading manufacturers including Sandvik Osprey, Hoganas, Praxair Surface Technologies, and CNPC Powder Group.

Kontaktujte nás nyní

Kontaktujte nás pro aktuální nabídky produktů a skladovou dostupnost.