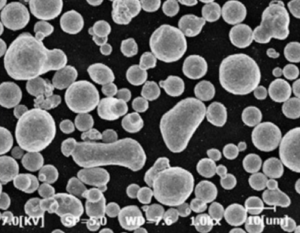

Prášek z titanové slitiny Ti-6Al-4V

Low oxygen pure titanium powder is the basis of powder metallurgy titanium production, is also one of the company£ªs leading products. At present, the company through HDH process, and oxygen control technology, the production of high-end ultra-fine low-oxygen pure Titanium Alloy Powder in the international leading position in the indicators, with the characteristics of ultrafine…

Malé MOQ

Flexibilní zásobování stovkami produktů

Podpora přizpůsobení

Prášek na míru podle odvětví

Rychlé odeslání

DHL Express, bezpečně a rychle přímo do vašich rukou

Low oxygen pure titanium powder is the basis of powder metallurgy titanium production, is also one of the company£ªs leading products. At present, the company through HDH process, and oxygen control technology, the production of high-end ultra-fine low-oxygen pure Titanium Alloy Powder in the international leading position in the indicators, with the characteristics of ultrafine powder size, ultra-low oxygen content, low impurities, to achieve the large-scale production of high-end low-oxygen pure titanium powder. It can produce a variety of titanium powder products, such as 150Ã×m, 75Ã×m, 45Ã×m, 10Ã×m, 3Ã×m and so on, with oxygen content reduced by 50% compared with conventional commercial products. The high-end ultra-fine low-oxygen pure titanium powder produced by the company has been listed as a qualified supplier of titanium powder in China£ªs first nuclear chemical project. At present, the domestic market share of our high-end low-oxygen pure titanium powder is more than 70%.

Výrobek?Specifikace

| Pure titanium powder | Mesh | Particle size¨P | PSD | Element¨×%¨Ø¡¥ | |||||||||

| D10 | D50 | D90 | Fe | Cl | Mg | Mn | Ano | C | N | H | O | ||

| -100mesh | 150Ã×m | 45-50 | 90-95 | 135-140 | 0.03 | 0.02 | 0.01 | 0.01 | 0.01 | 0.03 | 0.03 | 0.03 | 0.13 |

| -200mesh | 75Ã×m | 18-23 | 38-45 | 65-70 | 0.03 | 0.02 | 0.01 | 0.01 | 0.01 | 0.03 | 0.03 | 0.03 | 0.16 |

| -325mesh | 45Ã×m | 10-15 | 26-31 | 46-51 | 0.03 | 0.02 | 0.01 | 0.01 | 0.01 | 0.03 | 0.03 | 0.03 | 0.2 |

* Remark:Supporting customized according to customer requirements

Strroduct Features

- The powder has high purity, low oxygen.

- Ultrafine powder particle size.

- Mass production of 150Ã×m, 75Ã×m, 45Ã×m, 10Ã×m, 3Ã×m and other particle size products

- Hydride- dehydrogenation (HDH process)

- Monthly output of 35 tons, 420 tons of annual output.

Aplikace

Mainly used in hydrogen battery, powder metallurgy raw materials, surface coating agent, aluminum alloy additives, electric vacuum getter, spray, plating,MIM and other fields.

Proces rozmělňování:

- Titanium Sponge

- Vacuum High

- Temperature Hydrogenation

- Titanium Hydride Hydrogenation Granulation

- Titanium Hydride Powder

- Vacuum High Temperature Dehydrogenation

- Dehydrogenation Titanium

- Dehydrogenation Granulation

- Screening

- Inspection

- Finished Products

- Balení

Často kladené otázky (FAQ)

- How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

- What can you buy from us?

3D metal powder, MIM powder, Electronic paste, the products included are 316L, 17-4ph, H13, sendust,Inconel718,Inconel625m, Silver powder, silver paste, Rare earth products.

Kontaktujte nás nyní

Kontaktujte nás pro aktuální nabídky produktů a skladovou dostupnost.