Stainless Steel OP431 Powder

Overview of Stainless Steel OP431 Powder OP431 stainless steel belongs to the ferritic grade steels which contain chromium as the principal alloying element. The addition of aluminum enhances oxidation and corrosion resistance at high temperatures. Key characteristics of OP431 powder include: Excellent oxidation and corrosion resistance up to 1150¡«C Good creep resistance and thermal fatigue…

Piccolo MOQ

Sourcing flessibile per centinaia di prodotti

Supporto alla personalizzazione

Polvere personalizzata in base all'industria

Spedizione rapida

Con DHL Express, sicuro e veloce direttamente nelle vostre mani

Overview of Stainless Steel OP431 Powder

OP431 stainless steel belongs to the ferritic grade steels which contain chromium as the principal alloying element. The addition of aluminum enhances oxidation and corrosion resistance at high temperatures.

Key characteristics of OP431 powder include:

- Excellent oxidation and corrosion resistance up to 1150¡«C

- Good creep resistance and thermal fatigue strength

- Excellent thermo-mechanical stability

- High thermal conductivity and low thermal expansion

- Cost-effective compared to austenitic stainless steels

- Disponibile in varie granulometrie

OP431 powder is ideal for applications requiring oxidation resistance, thermal stability and moderate strength at elevated temperatures.

Chemical Composition of OP431 Powder

OP431 powder has the following nominal composition:

| Elemento | % Peso |

|---|---|

| Ferro (Fe) | Equilibrio |

| Cromo (Cr) | 16-18% |

| Alluminio (Al) | 3-5% |

| Yttrium (Y) | 0.2-0.5% |

| Carbonio (C) | 0,03% max |

| Silicio (Si) | Al massimo l'1% |

| Manganese (Mn) | Al massimo l'1% |

Chromium provides corrosion resistance while aluminum enables excellent oxidation resistance through formation of a protective alumina layer at high temperatures. Yttrium refines the grain size for additional strength.

Properties of OP431 Powder

Key properties of OP431 powder include:

| Proprietà | Valore |

|---|---|

| Densità | 7.3 g/cm3 |

| Punto di fusione | 1400-1450 circa |

| Conduttività termica | 29 W/mK |

| Resistività elettrica | 0.6 Ã×´Î.cm |

| Modulo di Young | 200 GPa |

| Rapporto di Poisson | 0.27-0.30 |

| Resistenza alla trazione | 450-650 MPa |

| Limite di snervamento | 280-480 MPa |

| Allungamento | 15-20% |

| Resistenza all'ossidazione | Eccellente fino a 1150 ¡«C |

The properties like high temperature strength, oxidation resistance, and thermal stability make OP431 suitable for demanding applications.

Production Method for OP431 Powder

OP431 powder can be produced via:

- Atomizzazione a gas?- High pressure inert gas used to atomize the molten alloy resulting in fine spherical powder ideal for AM.

- Atomizzazione dell'acqua?- High velocity water jet breaks up the molten stream producing irregular powder particles. Lower cost but higher oxygen pickup.

- Legame meccanico- Macinazione a sfere di miscele di polveri elementari eseguita con sinterizzazione e atomizzazione secondaria.

Gas atomization allows excellent control over particle size distribution, morphology, oxygen pickup and microstructure.

Applications of OP431 Powder

Typical applications of OP431 powder include:

- manifattura additiva?- Selective laser melting to produce complex parts needing high temperature oxidation resistance.

- Rivestimento con spruzzatura termica?- Applied via arc spraying to provide protective coatings on components operating at over 1000¡«C.

- Metallurgico per Brasatura?- For joining ferritic stainless steel parts in high temperature applications.

- Accenditori a combustibile solido?- Powder metallurgy igniter plugs used in industrial furnaces and turbines.

- Elaborazione metalli fusi?- Powder metallurgy conveyor rolls, tundishes and ladles used in molten metal handling.

Specifications of OP431 Powder

OP431 powder is available under various size ranges, shapes and grades:

- Dimensione particellare:dalle 15 alle 45 µm per i metodi AM, fino a 150 µm per i processi di spruzzatura termica.

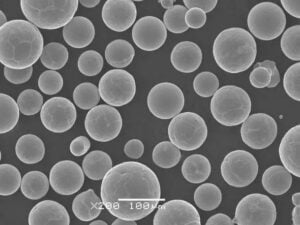

- Morfologia:forme sferiche, irregolari e miste. La polvere sferica ha un'eccellente fluidità.

- Purezza:?From commercial to high purity grades based on application requirements.

- Contenuto di ossigeno:Livelli mantenuti al di sotto di 2000 ppm per la maggior parte delle applicazioni.

- Portata:?Powder can be customized for flow rates above 25 s/50 g.

Global Suppliers of OP431 Powder

Some of the major global suppliers of OP431 powder include:

- Sandvik Osprey (Regno Unito)

- Höganäs (Svezia)

- Prodotti in polvere Carpenter (USA)

- Praxair Surface Technologies (USA)

- China National Petroleum Corporation Powder Group (CNPC)

These companies produce various grades of OP431 powder tailored for additive manufacturing, thermal spray, powder metallurgy and other high temperature applications.

Pricing of OP431 Powder

OP431 powder is priced higher than austenitic grades but lower than exotic alloys:

- Quantità?- $50-100 per kg for bulk orders above 500 kg. Smaller quantities are priced significantly higher.

- Qualità?- High purity, spherical powder with controlled characteristics demands premium pricing.

- Fornitore?- Large global suppliers offer competitive pricing owing to higher volumes.

- Geografia?- Prices vary between regions with Europe and North America being higher priced markets.

For critical applications, buyers should focus on quality rather than lowest cost while procuring OP431 powder.

Storage and Handling of OP431 Powder

OP431 powder requires the following storage and handling:

- Deve essere conservato in contenitori sigillati in gas inerte per evitare l'ossidazione

- Avoid accumulation of fine powder to minimize dust explosion risks

- Utilizzare DPI, ventilazione, messa a terra e pratiche di sicurezza adeguate durante la manipolazione.

- Previene il contatto tra la polvere e i materiali incompatibili

- Follow safety guidelines provided by supplier SDS

Proper protective measures must be taken when handling this reactive alloy powder.

Inspection and Testing of OP431 Powder

Key quality control tests performed on OP431 powder include:

- Analisi chimica tramite OES o XRF per assicurare che la composizione sia all'interno dei limiti specifici

- Distribuzione delle dimensioni delle particelle secondo lo standard ASTM B822

- Analisi morfologica tramite SEM

- Powder flow rate measured as per ASTM B213 standard

- Oxygen and nitrogen content testing by inert gas fusion

- Densità determinata mediante picnometria all'elio

- Microstructure characterization by XRD

Thorough testing ensures the powder meets the required chemical, physical and microstructural characteristics for the intended application.

Comparison Between OP431 and 316L Stainless Steel Powders

OP431 and 316L stainless steel powders are compared:

| Parametro | OP431 | 316L |

|---|---|---|

| Tipo | Ferritic | Austenitic |

| Contenuto di Cr | 16-18% | 16-18% |

| Ni content | – | 10-14% |

| Resistenza alle alte temperature | Più alto | Inferiore |

| Resistenza alla corrosione | Moderato | Eccellente |

| Costi | Inferiore | Più alto |

| APPLICAZIONI | Thermal spray, igniters | Automobilistico, edilizio |

| Saldabilità | Scarso | Eccellente |

OP431 offers much better high temperature strength whereas 316L provides excellent fabrication characteristics and corrosion resistance.

OP431 Powder FAQs

Q: How is OP431 powder produced?

A: OP431 powder is commercially produced using gas atomization, water atomization, and mechanical alloying followed by sintering. Gas atomization provides the best control of powder characteristics.

Q: What are the main applications of OP431 powder?

A: Key applications include thermal spray coatings, additive manufacturing, brazing filler, powder metallurgy igniter plugs, and high temperature molten metal handling components where oxidation resistance is needed.

Q: What is the typical OP431 powder size range used in metal AM?

A: For most metal AM processes, the ideal OP431 powder size range is 15-45 microns with spherical morphology and good powder flow characteristics.

Q: Does OP431 powder require any special handling precautions?

A: Yes, it is recommended to handle this reactive powder carefully under inert atmosphere using proper ventilation, grounding, and PPE.

Q: Where can I purchase OP431 powder suitable for thermal spray coatings?

A: For thermal spray applications requiring high temperature oxidation resistance, OP431 powder can be purchased from leading manufacturers including Sandvik Osprey, Hoganas, Praxair Surface Technologies, and CNPC Powder Group.

Contattateci ora

Contattateci per conoscere le ultime quotazioni dei prodotti e la disponibilità a magazzino.