Best Stainless Steel 316L Powder for 3D Printing

Overview of Stainless Steel 316L Powder 316L stainless steel belongs to the austenitic class of stainless steels. The addition of 2-3% molybdenum along with nickel and chromium imparts excellent pitting and crevice corrosion resistance in harsh environments. The ‘L’ denotes lower carbon content to avoid carbide precipitation during welding. Key characteristics of 316L powder include: Excellent corrosion resistance in harsh environments High oxidation and sulfidation resistance at elevated temperatures Very good weldability and formability Non-magnetic austenitic structure Available in range of particle size distributions 316L powder is suitable for applications requiring excellent corrosion resistance like chemical processing, pharmaceutical, food and beverage, marine equipment and biomedical implants. This article provides a…

小さなMOQ

何百もの製品に柔軟に対応

カスタマイズ・サポート

産業に応じてカスタマイズされたパウダー

迅速な出荷

DHLエクスプレスで、安全かつ迅速にお客様のお手元にお届けします。

Overview of Stainless Steel 316L Powder

316L stainless steel belongs to the austenitic class of stainless steels. The addition of 2-3% molybdenum along with nickel and chromium imparts excellent pitting and crevice corrosion resistance in harsh environments. The ‘L’ denotes lower carbon content to avoid carbide precipitation during welding.

Key characteristics of 316L powder include:

- Excellent corrosion resistance in harsh environments

- High oxidation and sulfidation resistance at elevated temperatures

- Very good weldability and formability

- Non-magnetic austenitic structure

- さまざまな粒度分布で利用可能

316L powder is suitable for applications requiring excellent corrosion resistance like chemical processing, pharmaceutical, food and beverage, marine equipment and biomedical implants. This article provides a detailed overview of 316L powder.

Chemical Composition of 316L Powder

The typical composition of 316L powder is:

| エレメント | 質量 % |

|---|---|

| 鉄 (Fe) | バランス |

| クロム | 16-18% |

| ニッケル (Ni) | 10-14% |

| モリブデン(Mo) | 2-3% |

| マンガン (Mn) | P 2% |

| ケイ素(Si) | P 1% |

| 炭素(C) | P 0.03% |

| リン (P) | ¨P 0.045% |

| 硫黄 (S) | P 0.03% |

Nickel enhances corrosion resistance while molybdenum addition improves resistance to pitting and crevice corrosion in environments containing chlorides. Low carbon content avoids carbide precipitation during welding.

Properties of 316L Powder

316L powder possesses the following properties:

| プロパティ | 価値 |

|---|---|

| 密度 | 7.9-8.1 g/cm3 |

| 融点 (Yūten) | 1370-1400¡4m |

| 熱伝導率 | 16 W/mK |

| 電気抵抗率 | 0.75 Ã×´Î.cm |

| ヤング係数 | 190-210 GPa |

| ポアソン比 | 0.27-0.30 |

| 引張強度 | 485-620 MPa |

| 降伏強度 | 170-310 MPa |

| 伸長 | 40-50% |

| 硬度 | 79-95 HRB |

316L offers excellent corrosion resistance combined with good formability and weldability. The austenitic structure provides good toughness and ductility.

Production Method for 316L Powder

Common production methods for 316L powder include:

- ガスアトマイゼーション?- Inert gas jets disintegrate molten 316L alloy stream into fine spherical powders with controlled size distribution.

- 水の原子化?- High pressure water jet impacts and disintegrates molten metal to produce fine irregular powder particles.

- 機械合金化?- 合金粉をブレンド後、ボールミル処理を行い、その後焼結、2次アトマイゼーションを実施する方法。

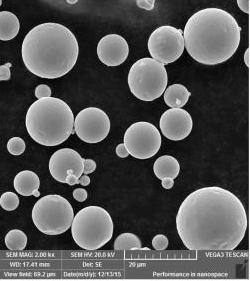

Gas atomization allows excellent control over particle characteristics like size, shape, oxygen pickup and microstructure.

Applications of 316L Powder

Typical applications of 316L powder include:

- 増材製造?- Powder bed fusion, binder jetting processes use 316L powder for chemical, marine, biomedical parts.

- 金属インジェクションモールディング?- To manufacture small, complex components needing corrosion resistance.

- サーマルスプレーコーティング?- Wire arc spray deposition to produce protective coatings in harsh environments.

- 溶接消耗品?- Used as filler material for joining 316L components providing excellent weld strength.

- 化学加工?- Powder metallurgy vessels, trays, baskets used in chemical and pharmaceutical industries.

Specifications of 316L Powder

316L powder is available under different size ranges, shapes and purity levels:

- 粒径:AM法では10~45Ø×m、溶射法では150Ø×mまで。

- 形態学:?Spherical, irregular and blended particle shapes. Smooth spherical powder provides optimal flow.

- 純粋性:?From commercial to high purity (99.9%) tailored to application requirements.

- 酸素濃度:?Levels maintained at 100-1000 ppm for most applications.

- 流量:25 s/50 g以上の流量用にカスタマイズされたパウダー。

Global Suppliers of 316L Powder

Some of the major global suppliers of 316L powder include:

- サンドビックオスプレイ(英国)

- ホーガネス (スウェーデン)

- カーペンター・パウダー・プロダクツ(米国)

- Praxair(アメリカ)

- エリコン・メトコ(スイス)

- LPW Technology (UK)

These companies produce various grades of 316L powder tailored for additive manufacturing, thermal spray, metal injection molding and other applications.

Pricing of 316L Powder

316L powder prices depend on factors like:

- 純度レベル

- 粒子の特性

- 注文数

- 追加処理

- メーカーと所在地

| グレード | 価格の範囲 |

|---|---|

| コマーシャル | 1 kgあたり15~25ドル |

| 高純度 | 1kg あたり $25-50 |

| 超微粒子 | 50~120円/kg |

| 特別等級 | 1 kg あたり 120-250 ドル |

Gas atomized, controlled particle size, high purity powders command much higher pricing over regular commercial grade 316L powder.

Storage and Handling of 316L Powder

316L powder should be handled with care to:

- Prevent contact with moisture, acids etc. leading to corrosion

- Avoid fine powder accumulation to minimize risk of dust explosions

- Use proper ventilation, PPE when handling fine powders

- Follow recommended practices from supplier SDS

- Store sealed containers in a dry, inert atmosphere

Proper protective measures must be taken when handling reactive alloy powders like 316L.

Inspection and Testing of 316L Powder

Key quality control tests performed on 316L powder:

- OESまたはXRFを使用した化学分析により、組成が規定の限界値内であることを確認します。

- ASTM B822規格に準拠した粒子サイズ分布

- SEMイメージングを使用した形態解析

- ASTM B213標準に従って測定された粉体流量

- ヘリウムピクノメトリーによる密度の決定

- ICP-MSによる不純物試験

- X線回折による微細構造評価

Thorough testing ensures the powder meets the required chemical, physical and microstructural characteristics for the intended application.

Comparison Between 316L and 304L Stainless Steel Powders

316L and 304L stainless steel powders compared:

| パラメータ | 316L | 304L |

|---|---|---|

| 作曲 | 鉄-クロム-ニッケル-モリブデン | Fe-Cr-Ni |

| 耐蝕性 | ずっといい | 調子が良い |

| 利用料 | 上 | 下げる |

| 温度耐性 | より良い | 調子が良い |

| 溶接性 | 素晴らしい | 素晴らしい |

| 空き状況 | 中程度 | 素晴らしい |

| アプリケーション | Marine, chemical industry | Consumer products, appliances |

316L offers substantially better corrosion resistance whereas 304L is more economical for less demanding applications.

316L Powder FAQs

Q: How is 316L stainless steel powder produced?

A: 316L powder is commercially produced using gas atomization, water atomization and mechanical alloying followed by sintering. Gas atomization offers the best control of powder characteristics.

Q: What are the main applications of 316L powder?

A: Key applications for 316L powder include additive manufacturing, metal injection molding, thermal spray coatings, and powder metallurgy parts for chemical, marine, pharmaceutical and food industries needing excellent corrosion resistance.

Q: What is the recommended 316L powder size for binder jetting AM?

A: For binder jetting process, the typical 316L powder size range is 20-45 microns with spherical morphology for optimal powder bed density and binder infiltration.

Q: Does 316L powder require special handling precautions?

A: Yes, 316L is a reactive alloy powder and should be handled carefully under controlled humidity and inert atmosphere using proper grounding, ventilation and PPE.

Q: Where can I buy 316L powder suitable for biomedical implants?

A: High purity, gas atomized 316L powder meeting biomedical specifications can be purchased from leading manufacturers like Sandvik Osprey, Hoganas, Carpenter Powder Products and LPW Technology.

お問い合わせ

最新の製品見積もりと在庫状況については、弊社までお問い合わせください。