17-4PH Stainless Steel Powder

Overview of 17-4PH Stainless Steel Powder 17-4PH is a precipitation hardening stainless steel powder widely used in additive manufacturing across aerospace, medical, automotive, and general engineering sectors. It offers an excellent combination of high strength, good corrosion resistance, and weldability. This article provides a detailed guide to 17-4PH powder covering composition, properties, AM process parameters,…

MOQ pequeno

Fornecimento flexível para centenas de produtos

Suporte à personalização

Pó personalizado de acordo com o setor

Envio rápido

Por DHL Express, seguro e rápido direto para suas mãos

Overview of 17-4PH Stainless Steel Powder

17-4PH is a precipitation hardening stainless steel powder widely used in additive manufacturing across aerospace, medical, automotive, and general engineering sectors. It offers an excellent combination of high strength, good corrosion resistance, and weldability.

This article provides a detailed guide to 17-4PH powder covering composition, properties, AM process parameters, applications, specifications, suppliers, handling, inspection, comparisons, pros and cons, and FAQs. Key information is presented in easy-to-reference tables.

Composition of 17-4PH Stainless Steel Powder

The composition of 17-4PH powder is:

| Elemento | % do Peso | Objetivo |

|---|---|---|

| Ferro | Equilíbrio | Elemento da matriz principal |

| Cromo | 15 – 17.5 | Resistência à oxidação |

| Cobre | 3 – 5 | Endurecimento por precipitação |

| Níquel | 3 – 5 | Austenite stabilizer |

| Nióbio | 0.15 – 0.45 | Formador de metal duro |

| Manganês | 1 max | Desoxidante |

| Silício | 1 max | Desoxidante |

| Carbono | 0.07 max | Strengthener and carbide former |

Copper enables precipitation hardening while chromium provides corrosion resistance.

Properties of 17-4PH Stainless Steel Powder

Key properties of 17-4PH powder include:

| Propriedade | Descrição |

|---|---|

| alta resistência | Up to 1310 MPa tensile strength when aged |

| Dureza | Up to 40 HRC in aged condition |

| Resistência à corrosão | Comparable to 316L stainless in many environments |

| Tenacidade | Superior to martensitic stainless steels |

| Resistência ao desgaste | Better than 300 series stainless steels |

| Estabilidade em altas temperaturas | Strength maintained up to 300¡«C |

The properties make 17-4PH suitable for diverse applications from aerospace components to injection molds.

AM Process Parameters for 17-4PH Powder

Typical parameters for printing 17-4PH powder include:

| Parâmetro | Valor típico | Objetivo |

|---|---|---|

| Altura da camada | 20-100 Ã×m | Balance speed and resolution |

| Potência do laser | 150-400 W | Derretimento suficiente sem evaporação |

| Velocidade de digitalização | 400-1000 mm/s | Densidade versus taxa de produção |

| Espaçamento da escotilha | 100-200 Ã×m | Density and mechanical properties |

| Estrutura de suporte | Mínimo | Fácil remoção |

| Prensagem isostática a quente | 1120¡«C, 100 MPa, 3 hrs | Eliminar a porosidade |

Parameters tailored for density, production rate, properties and post-processing needs.

Applications of 3D Printed 17-4PH Parts

Additively manufactured 17-4PH components are used in:

| Indústria | APLICATIVOS |

|---|---|

| Aeroespacial | Structural brackets, fixtures, actuators |

| Médico | Dental implants, surgical instruments |

| Automotivo | High strength fasteners, gears |

| Consumer products | Watch cases, sporting equipment |

| Industrial | End-use metal tooling, jigs, fixtures |

Benefits over machined 17-4PH parts include complex geometries, reduced lead time and machining allowances.

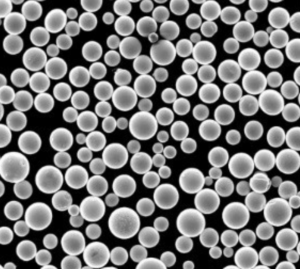

Specifications of 17-4PH Powder for AM

17-4PH powder must meet strict specifications:

| Parâmetro | Especificação |

|---|---|

| Intervalo de tamanho de partícula | 15-45 ×m típico |

| Formas das Partículas | Morfologia esférica |

| Densidade Aparente | > 4 g/cc |

| Densidade de Batida | > 6 g/cc |

| Vazão de fluxo do corredor | > 23 segundos para 50 g |

| Pureza | >99,9% |

| Conteúdo de oxigênio | < 100 ppm |

Distribuições de tamanho personalizadas e níveis de umidade controlados disponíveis.

Suppliers of 17-4PH Stainless Steel Powder

Reputable 17-4PH powder suppliers include:

| Fornecedor | Localização |

|---|---|

| Sandvik Osprey | Reino Unido |

| Aditivo Carpenter | Estados Unidos |

| Tecnologia LPW | Reino Unido |

| Erasteel | Suécia |

| Critical Materials | Estados Unidos |

| Praxair | Estados Unidos |

Prices range from $50/kg to $120/kg based on purity, size distribution and order volumes.

Handling and Storage of 17-4PH Powder

As a reactive material, careful 17-4PH powder handling is essential:

- Store sealed containers away from moisture, acids, ignition sources

- Use enchimento de gás inerte durante a transferência e o armazenamento

- Aterre o equipamento para dissipar cargas estáticas

- Avoid dust accumulation through extraction and ventilation

- Follow applicable safety guidelines

Técnicas adequadas garantem a condição ideal do pó.

Inspection and Testing of 17-4PH Powder

Os métodos de teste de qualidade incluem:

| Método | Parâmetros testados |

|---|---|

| Análise granulométrica | Distribuição de Tamanho de Partícula |

| imagens SEM | Morfologia da partícula |

| EDX | Química e composição |

| XRD | Fases presentes |

| Picnometria | Densidade |

| Vazão de fluxo do corredor | Fluidez do pó |

Os testes de acordo com as normas ASTM verificam a qualidade do pó e a consistência do lote.

Comparing 17-4PH to Alternative Alloy Powders

17-4PH compares to other alloys as:

| Liga | Força | Resistência à corrosão | Custo | Capacidade de impressão |

|---|---|---|---|---|

| 17-4PH | Excelente | Bom | Médio | Bom |

| 316L | Médio | Excelente | Médio | Excelente |

| IN718 | Muito alto | Bom | Alto | Razoável |

| CoCrMo | Médio | Razoável | Médio | Bom |

With its balanced properties, 17-4PH supersedes alternatives for many high-strength AM applications requiring corrosion resistance.

Pros and Cons of 17-4PH Powder for AM

| Prós | Contras |

|---|---|

| Alta relação resistência-peso | Lower oxidation resistance than austenitic stainless steels |

| Good combination of strength and corrosion resistance | Pós-processamento necessário, como HIP e tratamento térmico |

| Lower cost than exotic alloys | Controlled atmosphere storage needed |

| Established credentials in AM | Difícil de soldar e usinar |

| Properties match wrought material | Susceptible to pitting and crevice corrosion |

17-4PH enables high-performance printed parts across applications, though not suited for extreme environments.

Frequently Asked Questions about 17-4PH Powder

Q: What particle size range works best for printing 17-4PH alloy?

R: A faixa típica é de 15 a 45 mícrons. Ela proporciona ótima fluidez do pó combinada com alta resolução e peças densas.

Q: What post-processing methods are used on 17-4PH AM parts?

A: Hot isostatic pressing, solution annealing, aging, and machining are typically used to achieve full densification, relieve stresses, and improve surface finish.

Q: Which metal 3D printing process is ideal for 17-4PH alloy?

A: Selective laser melting (SLM), direct metal laser sintering (DMLS) and electron beam melting (EBM) can all effectively process 17-4PH powder.

Q: What industries use additively manufactured 17-4PH components?

A: Aerospace, medical, automotive, consumer products, industrial tooling, and oil and gas industries benefit from 3D printed 17-4PH parts.

Q: Does 17-4PH require support structures during printing?

A: Yes, minimal supports are needed on overhangs and bridged sections to prevent deformation and allow easy removal after printing.

Q: What defects can occur when printing 17-4PH powder?

A: Potential defects are cracking, porosity, distortion, incomplete fusion, and surface roughness. Most can be prevented with optimized parameters.

Q: What hardness is achievable with 17-4PH AM parts?

A: Solution-annealed 17-4PH has 25-30 HRC hardness while aging increases it to 35-40 HRC for enhanced wear resistance.

Q: What accuracy and surface finish is possible for 17-4PH printed parts?

A: Post-processed 17-4PH parts can achieve dimensional tolerances and surface finish comparable to CNC machined components.

Q: What is the key difference between 17-4 and 17-4PH grades?

A: 17-4PH has tighter chemistry control, lower impurities, and reduced sulfur for better ductility and impact properties compared to basic 17-4 grade.

Q: Is HIP required for all 17-4PH AM application?

A: While recommended, HIP may not be mandatory for non-critical applications. Heat treatment alone may suffice in some cases.

Entre em contato conosco agora

Entre em contato conosco para obter cotações recentes de produtos e disponibilidade de estoque.