Best 18Ni300 Powder for 3D printing

No Name Chemical Composition(wt%) 1 18Ni300 Ni17-19¨ÛMo4.5-5.2¨ÛCo8.5-9.5¨ÛTi0.6-0.8¨ÛAl0.05-0.15¨ÛFe(Bal.) 2 Hastelloy Alloy Fe17-20¨ÛCr20.5-23¨ÛMo8-10¨ÛW0.2-1¨ÛCo0.5-2.5¨ÛC0.05-0.15¨ÛNi(Bal.) 3 AlSi10Mg Si9-11¨ÛMg0.2-0.45¨ÛAl(Bal.) 4 CoCrW Cr26.5-29¨ÛW7-9¨ÛSi1.2-1.9¨ÛCo(Bal.) 5 Co28Cr6Mo Cr27-29¨ÛMo5-7¨ÛCo(Bal.) 6 Spherical Ti Powder Ti¡Ô99.9 7 TC4 Al5.5-6.8¨ÛV3.5-4.5¨ÛTi(Bal.) 8 TA15 Al5.5-7.1¨ÛV0.8-2.5¨ÛMo0.8-2¨ÛZr1.5-2.5¨ÛAl(Bal.) 9 316L Cr16.00-18.00¨Û Ni10.00-14.00¨ÛMo2.00-3.00¨ÛFe(Bal.) 10 S136 Cr12.0-14.0¨ÛSi0.8-1.0¨ÛV0.15-0.4¨ÛC0.2-0.45¨ÛFe(Bal.) 11 In625 Cr20-23 , Mo8-10 , Nb 3.15-4.15 , Co¨P1, Fe¨P1 , Ni (bal.) 12 In718 Cr17-21…

Малый MOQ

Гибкий поиск поставщиков для сотен продуктов

Поддержка персонализации

Подгонянный порошок согласно индустрии

Быстрая отгрузка

По DHL Express, безопасный и быстрый прямо к вам в руки

| Нет | Имя | Chemical Composition(wt%) |

| 1 | 18Ni300 | Ni17-19¨ÛMo4.5-5.2¨ÛCo8.5-9.5¨ÛTi0.6-0.8¨ÛAl0.05-0.15¨ÛFe(Bal.) |

| 2 | Hastelloy Alloy | Fe17-20¨ÛCr20.5-23¨ÛMo8-10¨ÛW0.2-1¨ÛCo0.5-2.5¨ÛC0.05-0.15¨ÛNi(Bal.) |

| 3 | AlSi10Mg | Si9-11¨ÛMg0.2-0.45¨ÛAl(Bal.) |

| 4 | CoCrW | Cr26.5-29¨ÛW7-9¨ÛSi1.2-1.9¨ÛCo(Bal.) |

| 5 | Co28Cr6Mo | Cr27-29¨ÛMo5-7¨ÛCo(Bal.) |

| 6 | Spherical Ti Powder | Ti¡Ô99.9 |

| 7 | TC4 | Al5.5-6.8¨ÛV3.5-4.5¨ÛTi(Bal.) |

| 8 | TA15 | Al5.5-7.1¨ÛV0.8-2.5¨ÛMo0.8-2¨ÛZr1.5-2.5¨ÛAl(Bal.) |

| 9 | 316L | Cr16.00-18.00¨Û Ni10.00-14.00¨ÛMo2.00-3.00¨ÛFe(Bal.) |

| 10 | S136 | Cr12.0-14.0¨ÛSi0.8-1.0¨ÛV0.15-0.4¨ÛC0.2-0.45¨ÛFe(Bal.) |

| 11 | In625 | Cr20-23 , Mo8-10 , Nb 3.15-4.15 , Co¨P1, Fe¨P1 , Ni (bal.) |

| 12 | In718 | Cr17-21 , Mo2.8-3.3 , Nb 4.75-5.5 , Co¨P1, Ni50-51 , Fe(Bal.) |

| 13 | Spherica WC | C3.7-4.2¨ÛW(Bal.) |

| 14 | Spherical Cr Powder | Cr¡Ô99.9 |

| 15 | Spherica Mo Powder | Mo¡Ô99.9 |

| 16 | Spherica Ta Powder | Ta¡Ô99.9 |

| 17 | Spherica W Powder | W¡Ô99.9 |

18Ni300 is a low carbon maraging steel, its strength, toughness and wear resistance are better than conventional steel materials, often used to make parts for automobile, medical and machinery industries

Product Properties

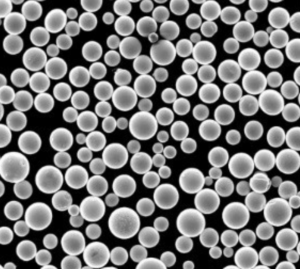

- Appearance: Grey powder

- Size: 15-53um

- PSD: D10=17.8Ã×m¨ÛD50=30.9Ã×m¨ÛD90=51.5Ã×m

- Note: Other 3D printing powders are available upon any custome requirements

Composition and Properties of 18Ni300 Powder

18Ni300 powder typically consists of approximately 18% nickel, 14% chromium, 4% molybdenum, and 2% manganese. These elements work synergistically to enhance the material£ªs overall performance. The powder is characterized by exceptional mechanical properties, including high tensile strength, excellent impact resistance, and superior fatigue strength. Moreover, 18Ni300 powder exhibits excellent resistance to oxidation, pitting, and crevice corrosion, making it highly suitable for harsh environments.

Manufacturing Process of 18Ni300 Powder

The production of 18Ni300 powder involves a complex series of manufacturing steps. Initially, the raw materials are carefully selected and meticulously blended to achieve the desired composition. The mixture is then melted in a controlled environment using advanced metallurgical techniques. Once melted, the alloy is rapidly cooled to form a fine powder through a process called atomization. The resulting powder is then carefully sieved and processed to remove any impurities, ensuring a high-purity final product.

Applications of 18Ni300 Powder

The versatility of 18Ni300 powder enables its utilization in various industries. Here are some prominent applications:

- Aerospace Industry: The aerospace sector relies heavily on high-performance materials, and 18Ni300 powder fits the bill perfectly. It is used in the manufacturing of aircraft components, including engine parts, landing gear, and structural elements, thanks to its exceptional strength-to-weight ratio and resistance to high temperatures.

- Oil and Gas Industry: In the demanding oil and gas sector, 18Ni300 powder is widely employed for producing valves, pumps, and pipelines. Its excellent corrosion resistance properties make it highly suitable for handling corrosive fluids and gases, ensuring reliable and long-lasting equipment.

- Chemical Industry: Chemical processing plants often deal with aggressive chemicals and corrosive environments. 18Ni300 powder finds application in the production of chemical reactors, heat exchangers, and storage tanks due to its ability to withstand harsh chemical conditions.

- Power Generation: Power plants require materials capable of withstanding high temperatures and pressures. 18Ni300 powder is utilized in the construction of gas and steam turbines, boilers, and heat recovery systems, providing enhanced efficiency and durability.

Заключение

In conclusion, the advent of 18Ni300 powder has significantly transformed the manufacturing industry. Its exceptional composition, mechanical properties, and resistance to corrosion make it a sought-after material for a wide range of applications. From aerospace to oil and gas, chemical to power generation, this high-performance alloy is proving its worth in diverse sectors. As the manufacturing industry continues to evolve, the advancements and potential of 18Ni300 powder are likely to shape the future of material engineering.

Часто задаваемые вопросы

1. What is the significance of 18Ni300 powder in the manufacturing industry??18Ni300 powder offers exceptional strength, durability, and corrosion resistance, making it highly valuable for various industrial applications, including aerospace, oil and gas, chemical, and power generation.

2. How is 18Ni300 powder manufactured??The production process involves carefully selecting and blending the raw materials, melting the mixture, atomizing it to form a fine powder, and then sieving and processing it to remove impurities.

3. What are the key properties of 18Ni300 powder??18Ni300 powder possesses high tensile strength, impact resistance, fatigue strength, and excellent resistance to oxidation, pitting, and crevice corrosion.

4. What industries benefit from using 18Ni300 powder??Industries such as aerospace, oil and gas, chemical, and power generation extensively use 18Ni300 powder for its exceptional properties and corrosion resistance in their respective applications.

5. How does 18Ni300 powder contribute to the development of sustainable manufacturing practices??By providing durability, resistance to corrosion, and enhanced performance, 18Ni300 powder enables the production of long-lasting, reliable equipment, reducing the need for frequent replacements and promoting sustainability in manufacturing processes.

Свяжитесь с нами сейчас

Пожалуйста, свяжитесь с нами, чтобы узнать последние цены на продукцию и наличие на складе.