Порошок тугоплавкого титанового сплава PREP

Обзор порошка тугоплавкого титанового сплава PREP Сплав PREP (Plasma Rotating Electrode Process) - это высокопроизводительный порошок тугоплавкого титанового сплава, предназначенный для аддитивного производства компонентов, требующих превосходных механических свойств при экстремальных температурах. В этой статье представлено полное руководство по порошку титанового сплава PREP, включающее состав, свойства, параметры печати, области применения, спецификации, поставщиков, обработку, контроль, сравнение,...

Малый MOQ

Гибкий поиск поставщиков для сотен продуктов

Поддержка персонализации

Подгонянный порошок согласно индустрии

Быстрая отгрузка

По DHL Express, безопасный и быстрый прямо к вам в руки

Overview of PREP Refractory Titanium Alloy Powder

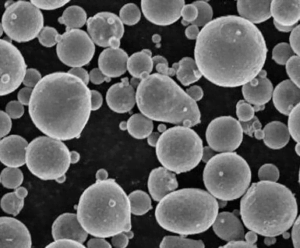

PREP (Plasma Rotating Electrode Process) alloy is a high-performance refractory titanium alloy powder designed for additive manufacturing of components needing excellent mechanical properties at extreme temperatures.

This article provides a comprehensive guide to PREP titanium alloy powder covering composition, properties, print parameters, applications, specifications, suppliers, handling, inspection, comparisons, pros and cons, and FAQs. Quantitative information is presented in easy-to-reference tables.

Composition of PREP Titanium Alloy Powder

PREP alloy has a complex composition containing various solute elements:

| Элемент | Весовые % | Цель |

|---|---|---|

| Титан | Баланс | Principal matrix element |

| Алюминий | 5 – 7 | Solid solution strengthener |

| Tin | 1 – 3 | Solid solution strengthener |

| Цирконий | 0.5 – 2 | Grain structure control |

| Молибден | 1 – 3 | Solid solution strengthener |

| Кремний | 0.5 – 1.5 | Коррозийная устойчивость |

| Ниобий | 1 – 3 | Carbide former |

| Тантал | 1 – 3 | Carbide former |

Trace amounts of boron and carbon are also added for grain boundary strengthening.

Properties of PREP Titanium Alloy Powder

PREP alloy exhibits an exceptional combination of properties:

| Имущество | Описание |

|---|---|

| высокая прочность | Excellent tensile and creep strength up to 700¡«C |

| Fatigue resistance | High fatigue life at elevated temperatures |

| Устойчивость к разрушению | Up to 100 MPa-©|m |

| Коррозийная устойчивость | Forms protective oxide scale |

| Термическая стабильность | Microstructural stability after prolonged exposures |

| Damage tolerance | Resistant to crack growth |

| биосовместимостью | Нетоксичный и гипоаллергенный |

The properties enable lightweight components for demanding applications.

AM Print Parameters for PREP Titanium Alloy Powder

Typical AM process parameters include:

| Параметр | Типичное значение | Цель |

|---|---|---|

| Layer height | 30-50 Ã×m | Resolution versus build speed |

| Laser power | 150-500 W | Sufficient melting without evaporation |

| Scan speed | 750-1500 mm/s | Density versus production rate |

| Hatch spacing | 80-120 Ã×m | Mechanical properties |

| Hot isostatic pressing | 900¡«C, 100 MPa, 3 hrs | Eliminate internal voids |

Parameters optimized for density, microstructure, build rate and post-processing requirements.

Applications of 3D Printed PREP Titanium Parts

PREP alloy components serve critical applications including:

| Промышленность | Компоненты |

|---|---|

| Аэрокосмическая отрасль | Turbine blades, compressor parts, mounts |

| Автомобильный | Connecting rods, valves, turbocharger wheels |

| Медицинский | Orthopedic implants, surgical tools |

| Химический | Pumps, valves, reaction vessels |

| Выработка электроэнергии | Hot gas path components |

Benefits over wrought equivalents include complex geometries and accelerated development.

Specifications of PREP Titanium Powder for AM

PREP alloy powder must meet strict specifications:

| Параметр | Спецификация |

|---|---|

| Диапазон размеров частиц | 15-45 Ã×m typical |

| Форма частиц | Spherical morphology |

| Кажущаяся плотность | >2.5 g/cc |

| Плотность при утрамбовке | >4.5 g/cc |

| Скорость потока холла | >35 sec for 50 g |

| Чистота | >99.95% |

| Содержание кислорода | <1000 ppm |

Custom size distributions and controlled oxygen levels available.

Suppliers of PREP Titanium Alloy Powder

PREP alloy powder is supplied by:

| Поставщик | Местоположение |

|---|---|

| Praxair | США |

| AP&C | Канада |

| Текна | Канада |

| Metalysis | Соединённое Королевство |

| Технология LPW | Соединённое Королевство |

| EOS | Германия |

Prices range from $250/kg to $450/kg based on quality, size distribution and order volume.

Handling and Storage of PREP Titanium Powder

As a reactive material, careful handling of PREP alloy powder is essential:

- Store sealed containers under inert gas like argon

- Prevent exposure to air and moisture during handling

- Use properly grounded equipment

- Avoid dust accumulation to minimize explosion risk

- Local exhaust ventilation recommended

- Wear appropriate PPE and avoid inhalation

Proper techniques and controls prevent powder oxidation.

Inspection and Testing of PREP Titanium Powder

PREP alloy powder batches are validated using:

| Метод | Parameters Tested |

|---|---|

| Гранулометрический анализ | Распределение размера частиц |

| Сканирующая электронная микроскопия | Particle morphology |

| EDX | Chemistry/composition |

| XRD | Phases present |

| Pycnometry | Плотность |

| Скорость потока холла | Текучесть порошка |

Testing per ASTM standards ensures batch-to-batch consistency.

Comparing PREP Alloy to Alternative Titanium Powders

PREP alloy compares to other titanium materials as:

| Сплав | Сила | Коррозийная устойчивость | Цена | Возможность печати |

|---|---|---|---|---|

| PREP | Отличный | Отличный | Высок | Хорошо |

| Ti64 | Хорошо | Хорошо | Средний | Справедливо |

| Ti6242 | Отличный | Хорошо | Высок | Справедливо |

| CP-Ti | Низкий | Отличный | Низкий | Отличный |

PREP provides the best all-round properties but at higher cost than workhorse alloys like Ti64.

Pros and Cons of PREP Titanium Powder for AM

| Преимущества | Минусы |

|---|---|

| Outstanding high temperature strength | Expensive compared to Ti64 and CP-Ti |

| Excellent thermomechanical fatigue resistance | Higher density than other titanium alloys |

| Complex geometries feasible | Controlled atmosphere handling mandatory |

| Lower anisotropy than Ti64 and CP-Ti | Processing very technique sensitive |

| Matching properties to PREP wrought forms | Limited suppliers and alloy variants |

PREP enables exceptional performance additive manufacturing but requires very rigorous control of process conditions.

Frequently Asked Questions about PREP Titanium Alloy Powder

Q: What is PREP titanium alloy used for in AM?

A: PREP alloy is used to 3D print lightweight aerospace and automotive components needing extremely high mechanical properties at temperatures up to 700¡«C.

Q: What particle size is recommended for printing PREP titanium alloy?

A: A powder size range of 15-45 microns provides a good balance of flowability, high resolution, and dense printed parts.

Q: Does PREP titanium require hot isostatic pressing after AM?

A: HIP is recommended to eliminate internal voids, maximize fatigue resistance and achieve full density. It may not be mandatory for non-critical applications.

Q: What material has properties closest to PREP titanium alloy?

A: Ti-6Al-4V has comparable density and good high temperature strength, but lower oxidation resistance compared to PREP alloys.

Q: What benefits does PREP alloy offer over Ti-6Al-4V in AM?

A: Key advantages are higher tensile and fatigue strength up to 700¡«C along with significantly better creep and thermo-mechanical fatigue resistance.

Q: What precision can be obtained with PREP titanium printed parts?

A: After post-processing, printed PREP components can achieve dimensional tolerances and surface finish comparable to CNC machined titanium parts.

Q: What defects can occur when printing PREP titanium alloy?

A: Potential defects are cracking, distortion, porosity, incomplete fusion, and surface roughness. Most can be minimized through optimized parameters.

Q: Can support structures be easily removed from PREP titanium AM parts?

A: Properly designed minimal supports are readily detachable after printing due to excellent mechanical properties of PREP alloys.

Q: What type of post-processing is typically done on PREP titanium components?

A: Hot isostatic pressing, heat treatment, abrasive flow machining, CNC machining, and electropolishing are commonly used post-processes.

Q: What is the key difference between Ti-6Al-4V Grade 5 and Grade 23?

A: Grade 5 has higher oxygen content for better powder flowability while Grade 23 has lower oxygen for superior fracture toughness and fatigue resistance.

Свяжитесь с нами сейчас

Пожалуйста, свяжитесь с нами, чтобы узнать последние цены на продукцию и наличие на складе.