17-4PH Stainless Steel Powder

Overview of 17-4PH Stainless Steel Powder 17-4PH is a precipitation hardening stainless steel powder widely used in additive manufacturing across aerospace, medical, automotive, and general engineering sectors. It offers an excellent combination of high strength, good corrosion resistance, and weldability. This article provides a detailed guide to 17-4PH powder covering composition, properties, AM process parameters,…

Klein MOQ

Flexibele sourcing voor honderden producten

Ondersteuning voor maatwerk

Aangepast poeder volgens de industrie

Snelle verzending

Per DHL Express, veilig en snel in uw handen

Overview of 17-4PH Stainless Steel Powder

17-4PH is a precipitation hardening stainless steel powder widely used in additive manufacturing across aerospace, medical, automotive, and general engineering sectors. It offers an excellent combination of high strength, good corrosion resistance, and weldability.

This article provides a detailed guide to 17-4PH powder covering composition, properties, AM process parameters, applications, specifications, suppliers, handling, inspection, comparisons, pros and cons, and FAQs. Key information is presented in easy-to-reference tables.

Composition of 17-4PH Stainless Steel Powder

The composition of 17-4PH powder is:

| Element | Gewichts % | Doel |

|---|---|---|

| IJzer | Balans | Principal matrix element |

| Chroom | 15 – 17.5 | Oxidatiebestendigheid |

| Koper | 3 – 5 | Neerslaghardening |

| Nikkel | 3 – 5 | Austenite stabilizer |

| Niobium | 0.15 – 0.45 | Hardmetalen former |

| Mangaan | 1 max | Deoxidatiemiddel |

| Silicium | 1 max | Deoxidatiemiddel |

| Koolstof | 0.07 max | Strengthener and carbide former |

Copper enables precipitation hardening while chromium provides corrosion resistance.

Properties of 17-4PH Stainless Steel Powder

Key properties of 17-4PH powder include:

| Onroerend goed | Beschrijving |

|---|---|

| hoge sterkte | Up to 1310 MPa tensile strength when aged |

| Hardheid | Up to 40 HRC in aged condition |

| Weerstand tegen corrosie | Comparable to 316L stainless in many environments |

| Taaiheid | Superior to martensitic stainless steels |

| Slijtvastheid | Better than 300 series stainless steels |

| Stabiliteit bij hoge temperaturen | Strength maintained up to 300¡«C |

The properties make 17-4PH suitable for diverse applications from aerospace components to injection molds.

AM Process Parameters for 17-4PH Powder

Typical parameters for printing 17-4PH powder include:

| Parameter | Typische waarde | Doel |

|---|---|---|

| Laaghoogte | 20-100 Ã×m | Balance speed and resolution |

| Laservermogen | 150-400 W | Voldoende smelten zonder verdamping |

| Scansnelheid | 400-1000 mm/s | Dichtheid versus productiesnelheid |

| Afstand tussen luiken | 100-200 Ã×m | Dichtheid en mechanische eigenschappen |

| Ondersteunende structuur | Minimaal | Gemakkelijk verwijderen |

| Heet isostatisch persen | 1120¡«C, 100 MPa, 3 hrs | Poreusheid elimineren |

Parameters tailored for density, production rate, properties and post-processing needs.

Applications of 3D Printed 17-4PH Parts

Additively manufactured 17-4PH components are used in:

| Industrie | TOEPASSINGEN |

|---|---|

| Lucht- en ruimtevaart | Structural brackets, fixtures, actuators |

| Medisch | Dental implants, surgical instruments |

| Automobielen | High strength fasteners, gears |

| Consumer products | Watch cases, sporting equipment |

| Industriële | End-use metal tooling, jigs, fixtures |

Benefits over machined 17-4PH parts include complex geometries, reduced lead time and machining allowances.

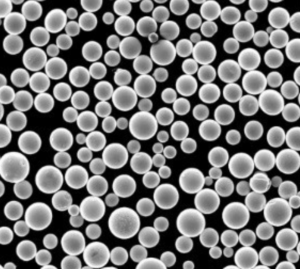

Specifications of 17-4PH Powder for AM

17-4PH powder must meet strict specifications:

| Parameter | Specificatie |

|---|---|

| Maatbereik van de deeltjes | 15-45 Ã×m typisch |

| Vorm van deeltjes | Bolvormige morfologie |

| Schijnbare dichtheid | > 4 g/cc |

| Tapdichtheid | > 6 g/cc |

| Halflow | > 23 sec voor 50 g |

| Zuiverheid | >99,9% |

| Zuurstofgehalte | <100 ppm |

Maatverdeling en gecontroleerde vochtigheidsniveaus op maat verkrijgbaar.

Suppliers of 17-4PH Stainless Steel Powder

Reputable 17-4PH powder suppliers include:

| Provider | Locatie |

|---|---|

| Sandvik Osprey | VK |

| Carpenter Additive | Verenigde Staten |

| LPW-technologie | VK |

| Erasteel | Zweden |

| Critical Materials | Verenigde Staten |

| Praxair | Verenigde Staten |

Prices range from $50/kg to $120/kg based on purity, size distribution and order volumes.

Handling and Storage of 17-4PH Powder

As a reactive material, careful 17-4PH powder handling is essential:

- Store sealed containers away from moisture, acids, ignition sources

- Gebruik opvulling met inert gas tijdens transport en opslag

- Apparatuur aarden om statische ladingen af te voeren

- Avoid dust accumulation through extraction and ventilation

- Follow applicable safety guidelines

De juiste technieken zorgen voor een optimale poederconditie.

Inspection and Testing of 17-4PH Powder

Kwaliteitstestmethoden zijn onder andere:

| Methode | Geteste parameters |

|---|---|

| Zeefanalyse | Particle size distribution |

| SEM-beeldvorming | Deeltjesmorfologie |

| EDX | Chemie en samenstelling |

| XRD | Aanwezige fasen |

| Pyknometrie | Dichtheid |

| Halflow | Poeder vloei-eigenschappen |

Testen volgens ASTM-normen verifiëren de kwaliteit van het poeder en de consistentie van de batch.

Comparing 17-4PH to Alternative Alloy Powders

17-4PH compares to other alloys as:

| Legering | Kracht | Weerstand tegen corrosie | Kosten | Printbaarheid |

|---|---|---|---|---|

| 17-4PH | Uitmuntend | Goed | Medium | Goed |

| 316L | Medium | Uitmuntend | Medium | Uitmuntend |

| IN718 | Heel hoog | Goed | Hoog | Redelijk |

| CoCrMo | Medium | Redelijk | Medium | Goed |

With its balanced properties, 17-4PH supersedes alternatives for many high-strength AM applications requiring corrosion resistance.

Pros and Cons of 17-4PH Powder for AM

| Voordelen | Nadelen |

|---|---|

| Hoge sterkte-gewichtsverhouding | Lower oxidation resistance than austenitic stainless steels |

| Good combination of strength and corrosion resistance | Vereiste nabewerking zoals HIP en warmtebehandeling |

| Lower cost than exotic alloys | Controlled atmosphere storage needed |

| Established credentials in AM | Moeilijk te lassen en te bewerken |

| Properties match wrought material | Susceptible to pitting and crevice corrosion |

17-4PH enables high-performance printed parts across applications, though not suited for extreme environments.

Frequently Asked Questions about 17-4PH Powder

Q: What particle size range works best for printing 17-4PH alloy?

A: Een typisch bereik is 15-45 micron. Het biedt een optimale poederstroom in combinatie met een hoge resolutie en dichte onderdelen.

Q: What post-processing methods are used on 17-4PH AM parts?

A: Hot isostatic pressing, solution annealing, aging, and machining are typically used to achieve full densification, relieve stresses, and improve surface finish.

Q: Which metal 3D printing process is ideal for 17-4PH alloy?

A: Selective laser melting (SLM), direct metal laser sintering (DMLS) and electron beam melting (EBM) can all effectively process 17-4PH powder.

Q: What industries use additively manufactured 17-4PH components?

A: Aerospace, medical, automotive, consumer products, industrial tooling, and oil and gas industries benefit from 3D printed 17-4PH parts.

Q: Does 17-4PH require support structures during printing?

A: Yes, minimal supports are needed on overhangs and bridged sections to prevent deformation and allow easy removal after printing.

Q: What defects can occur when printing 17-4PH powder?

A: Potential defects are cracking, porosity, distortion, incomplete fusion, and surface roughness. Most can be prevented with optimized parameters.

Q: What hardness is achievable with 17-4PH AM parts?

A: Solution-annealed 17-4PH has 25-30 HRC hardness while aging increases it to 35-40 HRC for enhanced wear resistance.

Q: What accuracy and surface finish is possible for 17-4PH printed parts?

A: Post-processed 17-4PH parts can achieve dimensional tolerances and surface finish comparable to CNC machined components.

Q: What is the key difference between 17-4 and 17-4PH grades?

A: 17-4PH has tighter chemistry control, lower impurities, and reduced sulfur for better ductility and impact properties compared to basic 17-4 grade.

Q: Is HIP required for all 17-4PH AM application?

A: While recommended, HIP may not be mandatory for non-critical applications. Heat treatment alone may suffice in some cases.

Neem nu contact met ons op

Neem contact met ons op voor recente productoffertes en beschikbaarheid van voorraad.