Best Stainless Steel 316L Powder for 3D Printing

Overview of Stainless Steel 316L Powder 316L stainless steel belongs to the austenitic class of stainless steels. The addition of 2-3% molybdenum along with nickel and chromium imparts excellent pitting and crevice corrosion resistance in harsh environments. The ‘L’ denotes lower carbon content to avoid carbide precipitation during welding. Key characteristics of 316L powder include:…

Klein MOQ

Flexibele sourcing voor honderden producten

Ondersteuning voor maatwerk

Aangepast poeder volgens de industrie

Snelle verzending

Per DHL Express, veilig en snel in uw handen

Overview of Stainless Steel 316L Powder

316L stainless steel belongs to the austenitic class of stainless steels. The addition of 2-3% molybdenum along with nickel and chromium imparts excellent pitting and crevice corrosion resistance in harsh environments. The ‘L’ denotes lower carbon content to avoid carbide precipitation during welding.

Key characteristics of 316L powder include:

- Excellent corrosion resistance in harsh environments

- High oxidation and sulfidation resistance at elevated temperatures

- Very good weldability and formability

- Non-magnetic austenitic structure

- Verkrijgbaar in verschillende deeltjesgrootteverdelingen

316L powder is suitable for applications requiring excellent corrosion resistance like chemical processing, pharmaceutical, food and beverage, marine equipment and biomedical implants. This article provides a detailed overview of 316L powder.

Chemical Composition of 316L Powder

The typical composition of 316L powder is:

| Element | Gewichts % |

|---|---|

| IJzer (Fe) | Balans |

| Chroom (Cr) | 16-18% |

| Nikkel (Ni) | 10-14% |

| Molybdeen (Mo) | 2-3% |

| Mangaan (Mn) | ¨P 2% |

| Silicium (Si) | ¨P 1% |

| Koolstof (C) | ¨P 0.03% |

| Fosfor (P) | ¨P 0.045% |

| Zwavel (S) | ¨P 0.03% |

Nickel enhances corrosion resistance while molybdenum addition improves resistance to pitting and crevice corrosion in environments containing chlorides. Low carbon content avoids carbide precipitation during welding.

Properties of 316L Powder

316L powder possesses the following properties:

| Onroerend goed | Waarde |

|---|---|

| Dichtheid | 7,9-8,1 g/cm3 |

| Smeltpunt | 1370-1400¡«C |

| Thermische geleidbaarheid | 16 W/mK |

| Elektrische resistiviteit | 0.75 Ã×´Î.cm |

| Elasticiteitsmodulus | 190-210 GPa |

| Poissonconstante | 0.27-0.30 |

| Treksterkte | 485-620 MPa |

| Rekgrens | 170-310 MPa |

| Verlenging | 40-50% |

| Hardheid | 79-95 HRB |

316L offers excellent corrosion resistance combined with good formability and weldability. The austenitic structure provides good toughness and ductility.

Production Method for 316L Powder

Common production methods for 316L powder include:

- Gasverstuiving?- Inert gas jets disintegrate molten 316L alloy stream into fine spherical powders with controlled size distribution.

- Verstuiven van water?- High pressure water jet impacts and disintegrates molten metal to produce fine irregular powder particles.

- Mechanische legering?- Kogelmolen van gemengde elementaire poeders gevolgd door sinteren en secundaire atomisering.

Gas atomization allows excellent control over particle characteristics like size, shape, oxygen pickup and microstructure.

Applications of 316L Powder

Typical applications of 316L powder include:

- additive manufacturing?- Powder bed fusion, binder jetting processes use 316L powder for chemical, marine, biomedical parts.

- Metaalspuitgieten?- To manufacture small, complex components needing corrosion resistance.

- Thermische spraycoatings?- Wire arc spray deposition to produce protective coatings in harsh environments.

- Lasmaterialen?- Used as filler material for joining 316L components providing excellent weld strength.

- Chemische verwerking?- Powder metallurgy vessels, trays, baskets used in chemical and pharmaceutical industries.

Specifications of 316L Powder

316L powder is available under different size ranges, shapes and purity levels:

- Grootte deeltjes:?From 10-45 Ã×m for AM methods, up to 150 Ã×m for thermal spray processes.

- Morfologie:?Spherical, irregular and blended particle shapes. Smooth spherical powder provides optimal flow.

- Zuiverheid:?From commercial to high purity (99.9%) tailored to application requirements.

- Zuurstofgehalte:?Levels maintained at 100-1000 ppm for most applications.

- Stroomsnelheid:Poeder aangepast voor stroomsnelheden boven 25 s/50 g.

Global Suppliers of 316L Powder

Some of the major global suppliers of 316L powder include:

- Sandvik Osprey (Verenigd Koninkrijk)

- Höganäs (Zweden)

- Carpenter Powder Products (USA)

- Praxair (VS)

- Oerlikon Metco (Switzerland)

- LPW Technology (UK)

These companies produce various grades of 316L powder tailored for additive manufacturing, thermal spray, metal injection molding and other applications.

Pricing of 316L Powder

316L powder prices depend on factors like:

- Zuiverheidsniveaus

- Kenmerk van deeltjes

- Bestelhoeveelheid

- Verdere verwerking

- Producent en geografische ligging

| Rang | Prijsbereik |

|---|---|

| Commercieel | 15-25 per kg |

| Hoge zuiverheid | $25-50 per kg |

| Ultrafijn | $50-120 per kg |

| Bijzondere klasse | $120-250 per kg |

Gas atomized, controlled particle size, high purity powders command much higher pricing over regular commercial grade 316L powder.

Storage and Handling of 316L Powder

316L powder should be handled with care to:

- Prevent contact with moisture, acids etc. leading to corrosion

- Avoid fine powder accumulation to minimize risk of dust explosions

- Use proper ventilation, PPE when handling fine powders

- Follow recommended practices from supplier SDS

- Store sealed containers in a dry, inert atmosphere

Proper protective measures must be taken when handling reactive alloy powders like 316L.

Inspection and Testing of 316L Powder

Key quality control tests performed on 316L powder:

- Chemische analyse met OES of XRF om de samenstelling binnen de gespecificeerde limieten te garanderen

- Deeltjesgrootteverdeling volgens ASTM B822-standaard

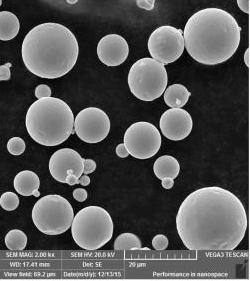

- Morfologische analyse middels SEM-beelden

- Powder flow rate measured as per ASTM B213 standard

- dichtheidsbepaling d.m.v. pycnometrie met helium

- Onzuiverheidstesten door middel van ICP-MS

- Microstructure characterization by X-ray diffraction

Thorough testing ensures the powder meets the required chemical, physical and microstructural characteristics for the intended application.

Comparison Between 316L and 304L Stainless Steel Powders

316L and 304L stainless steel powders compared:

| Parameter | 316L | 304L |

|---|---|---|

| Compositie | Fe-Cr-Ni-Mo | Fe-Cr-Ni |

| Weerstand tegen corrosie | Heel veel beter | Goed |

| Kosten | Hoger | Lager |

| Temperature resistance | Betere | Goed |

| Lasbaarheid | Uitmuntend | Uitmuntend |

| Beschikbaarheid | Gewoonlijk | Uitmuntend |

| TOEPASSINGEN | Marine, chemical industry | Consumentenproducten, apparaten |

316L offers substantially better corrosion resistance whereas 304L is more economical for less demanding applications.

316L Powder FAQs

Q: How is 316L stainless steel powder produced?

A: 316L powder is commercially produced using gas atomization, water atomization and mechanical alloying followed by sintering. Gas atomization offers the best control of powder characteristics.

Q: What are the main applications of 316L powder?

A: Key applications for 316L powder include additive manufacturing, metal injection molding, thermal spray coatings, and powder metallurgy parts for chemical, marine, pharmaceutical and food industries needing excellent corrosion resistance.

Q: What is the recommended 316L powder size for binder jetting AM?

A: For binder jetting process, the typical 316L powder size range is 20-45 microns with spherical morphology for optimal powder bed density and binder infiltration.

Q: Does 316L powder require special handling precautions?

A: Yes, 316L is a reactive alloy powder and should be handled carefully under controlled humidity and inert atmosphere using proper grounding, ventilation and PPE.

Q: Where can I buy 316L powder suitable for biomedical implants?

A: High purity, gas atomized 316L powder meeting biomedical specifications can be purchased from leading manufacturers like Sandvik Osprey, Hoganas, Carpenter Powder Products and LPW Technology.

Neem nu contact met ons op

Neem contact met ons op voor recente productoffertes en beschikbaarheid van voorraad.