17-4PH Stainless Steel Powder

Overview of 17-4PH Stainless Steel Powder 17-4PH is a precipitation hardening stainless steel powder widely used in additive manufacturing across aerospace, medical, automotive, and general engineering sectors. It offers an excellent combination of high strength, good corrosion resistance, and weldability. This article provides a detailed guide to 17-4PH powder covering composition, properties, AM process parameters,…

Małe MOQ

Elastyczne zaopatrzenie dla setek produktów

Wsparcie w zakresie dostosowywania

Dostosowany proszek według branży

Szybka wysyłka

DHL Express, bezpiecznie i szybko bezpośrednio do Twoich rąk

Overview of 17-4PH Stainless Steel Powder

17-4PH is a precipitation hardening stainless steel powder widely used in additive manufacturing across aerospace, medical, automotive, and general engineering sectors. It offers an excellent combination of high strength, good corrosion resistance, and weldability.

This article provides a detailed guide to 17-4PH powder covering composition, properties, AM process parameters, applications, specifications, suppliers, handling, inspection, comparisons, pros and cons, and FAQs. Key information is presented in easy-to-reference tables.

Composition of 17-4PH Stainless Steel Powder

The composition of 17-4PH powder is:

| Element | Waga % | Cel |

|---|---|---|

| Żelazo | Równowaga | Principal matrix element |

| Chrom | 15 – 17.5 | Odporność na utlenianie |

| Miedź | 3 – 5 | Utwardzenie wydzieleniowe |

| Nikiel | 3 – 5 | Austenite stabilizer |

| Niob | 0.15 – 0.45 | Forma z węglików spiekanych |

| Mangan | 1 maks | Odtleniacz |

| Krzem | 1 maks | Odtleniacz |

| Węgiel | 0.07 max | Strengthener and carbide former |

Copper enables precipitation hardening while chromium provides corrosion resistance.

Properties of 17-4PH Stainless Steel Powder

Key properties of 17-4PH powder include:

| Nieruchomość | Opis |

|---|---|

| bardzo wysoka wytrzymałość | Up to 1310 MPa tensile strength when aged |

| Twardość | Up to 40 HRC in aged condition |

| Odporność przeciwkorozyjna | Comparable to 316L stainless in many environments |

| Wytrzymałość | Superior to martensitic stainless steels |

| Odporność na zużycie | Better than 300 series stainless steels |

| Stabilność w wysokich temperaturach | Strength maintained up to 300¡«C |

The properties make 17-4PH suitable for diverse applications from aerospace components to injection molds.

AM Process Parameters for 17-4PH Powder

Typical parameters for printing 17-4PH powder include:

| Parametr | Wartość typowa | Cel |

|---|---|---|

| Wysokość warstwy | 20-100 Ã×m | Balance speed and resolution |

| Moc lasera | 150-400 W | Sufficient melting without evaporation |

| Prędkość skanowania | 400-1000 mm/s | Gęstość a szybkość produkcji |

| Rozstaw włazów | 100-200 Ã×m | Density and mechanical properties |

| Support structure | Minimalny | Easy removal |

| Prasowanie izostatyczne na gorąco | 1120¡«C, 100 MPa, 3 hrs | Eliminacja porowatości |

Parameters tailored for density, production rate, properties and post-processing needs.

Applications of 3D Printed 17-4PH Parts

Additively manufactured 17-4PH components are used in:

| Przemysł | APLIKACJE |

|---|---|

| Astronautyka | Structural brackets, fixtures, actuators |

| Medical | Dental implants, surgical instruments |

| Motoryzacja | High strength fasteners, gears |

| Consumer products | Watch cases, sporting equipment |

| Przemysłowy | End-use metal tooling, jigs, fixtures |

Benefits over machined 17-4PH parts include complex geometries, reduced lead time and machining allowances.

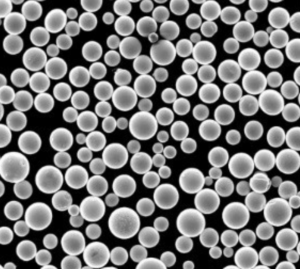

Specifications of 17-4PH Powder for AM

17-4PH powder must meet strict specifications:

| Parametr | Specyfikacja |

|---|---|

| Zakres rozmiarów cząstek | 15-45 Ã×m typowo |

| Kształt cząstki | Sferyczna morfologia |

| Gęstość Nasypowa | > 4 g/cc |

| Gęstość usypu | > 6 g/cc |

| Przepływ w hali | > 23 s dla 50 g |

| Czystość | >99,9% |

| Zawartość tlenu | <100 ppm |

Dostępne są niestandardowe rozkłady wielkości i kontrolowane poziomy wilgotności.

Suppliers of 17-4PH Stainless Steel Powder

Reputable 17-4PH powder suppliers include:

| Dostawca | Lokalizacja |

|---|---|

| Sandvik Osprey | Wielka Brytania |

| Carpenter Additive | USA |

| Technologia LPW | Wielka Brytania |

| Erasteel | Szwecja |

| Critical Materials | USA |

| Praxair | USA |

Prices range from $50/kg to $120/kg based on purity, size distribution and order volumes.

Handling and Storage of 17-4PH Powder

As a reactive material, careful 17-4PH powder handling is essential:

- Przechowywać szczelnie zamknięte pojemniki z dala od wilgoci, kwasów, źródeł zapłonu

- Use inert gas padding during transfer and storage

- Uziemienie sprzętu w celu rozproszenia ładunków elektrostatycznych

- Avoid dust accumulation through extraction and ventilation

- Follow applicable safety guidelines

Właściwe techniki zapewniają optymalny stan proszku.

Inspection and Testing of 17-4PH Powder

Metody testowania jakości obejmują:

| Metoda | Testowane parametry |

|---|---|

| Analiza sitowa | Rozpiętość wielkości cząsteczek |

| Mikroskopia SEM | Morfologia cząstek |

| EDX | Chemia i skład |

| XRD | Obecne fazy |

| Piknometria | Gęstość |

| Przepływ w hali | Płynność proszków |

Testowanie zgodnie z normami ASTM weryfikuje jakość proszku i spójność partii.

Comparing 17-4PH to Alternative Alloy Powders

17-4PH compares to other alloys as:

| Stop | Siła | Odporność przeciwkorozyjna | Koszt | Możliwość drukowania |

|---|---|---|---|---|

| 17-4PH | Wyśmienicie | Dobrze | Średnie | Dobrze |

| 316L | Średnie | Wyśmienicie | Średnie | Wyśmienicie |

| IN718 | Bardzo wysokie | Dobrze | Wysoki | Uczciwa |

| CoCrMo | Średnie | Uczciwa | Średnie | Dobrze |

With its balanced properties, 17-4PH supersedes alternatives for many high-strength AM applications requiring corrosion resistance.

Pros and Cons of 17-4PH Powder for AM

| Plusy | Wady |

|---|---|

| Wysoki stosunek wytrzymałości do masy | Lower oxidation resistance than austenitic stainless steels |

| Good combination of strength and corrosion resistance | Required post-processing like HIP and heat treatment |

| Lower cost than exotic alloys | Controlled atmosphere storage needed |

| Established credentials in AM | Trudne do spawania i obróbki |

| Properties match wrought material | Susceptible to pitting and crevice corrosion |

17-4PH enables high-performance printed parts across applications, though not suited for extreme environments.

Frequently Asked Questions about 17-4PH Powder

Q: What particle size range works best for printing 17-4PH alloy?

A: A typical range is 15-45 microns. It provides optimal powder flowability combined with high resolution and dense parts.

Q: What post-processing methods are used on 17-4PH AM parts?

A: Hot isostatic pressing, solution annealing, aging, and machining are typically used to achieve full densification, relieve stresses, and improve surface finish.

Q: Which metal 3D printing process is ideal for 17-4PH alloy?

A: Selective laser melting (SLM), direct metal laser sintering (DMLS) and electron beam melting (EBM) can all effectively process 17-4PH powder.

Q: What industries use additively manufactured 17-4PH components?

A: Aerospace, medical, automotive, consumer products, industrial tooling, and oil and gas industries benefit from 3D printed 17-4PH parts.

Q: Does 17-4PH require support structures during printing?

A: Yes, minimal supports are needed on overhangs and bridged sections to prevent deformation and allow easy removal after printing.

Q: What defects can occur when printing 17-4PH powder?

A: Potential defects are cracking, porosity, distortion, incomplete fusion, and surface roughness. Most can be prevented with optimized parameters.

Q: What hardness is achievable with 17-4PH AM parts?

A: Solution-annealed 17-4PH has 25-30 HRC hardness while aging increases it to 35-40 HRC for enhanced wear resistance.

Q: What accuracy and surface finish is possible for 17-4PH printed parts?

A: Post-processed 17-4PH parts can achieve dimensional tolerances and surface finish comparable to CNC machined components.

Q: What is the key difference between 17-4 and 17-4PH grades?

A: 17-4PH has tighter chemistry control, lower impurities, and reduced sulfur for better ductility and impact properties compared to basic 17-4 grade.

Q: Is HIP required for all 17-4PH AM application?

A: While recommended, HIP may not be mandatory for non-critical applications. Heat treatment alone may suffice in some cases.

Skontaktuj się z nami teraz

Prosimy o kontakt w celu uzyskania aktualnych ofert i dostępności produktów.